Building Mechanical and conception design:

We are aiming to provide our customers the suitable and perfect mechanical design for the new, renovating, upgrading, expansion buildings based on the up-to-date code, standard and the guidelines in the construction industry.

The scope of our client covered building owners, architects, developers, properties management companies

We provide building environment system technologies in:

- HVAC

- Plumbing (Storm, Sanitary and Potable)

- Fire protection and sprinklers

- Small commercial refrigeration design

- DDC and pneumatic control system

HVAC

[metaslider id=577]

Plumbing

[metaslider id=582]

Small commercial refrigeration design

[metaslider id=586]

DDC and pneumatic control system

[metaslider id=593]

We can help you through:

- Design-Bid- Build Projects

- Domestic Re-piping & Upgrade Projects

Our design procedure includes the writing the basis of the design, the conception of the construction drawing, ventilation drawing, heating drawing, details drawing and schedule and specification drawing.

We use the most relevant software to create our design and some of them are the:

- CARRIER Hourly Analysis Program for load calculation and sizing system components.

- ASHRAE Duct Fitting Database for the duct system design

- HVAC PRO Solution for heating design

- AUTOCAD for the drawings

- SIEMENS BAS for Automation (APOGEE Powers Process Control Language (PPCL))

We are dedicated to design your system to meet your specific needs.

Duct Cleaning

A lot of dust and dirt can build up in your air ducts over the years, and some of the following factors will increase the need for air duct cleaning: Pets, renovation or remodeling projects, cigarette/cigar smoke, water damage, and occupants suffering from allergies/asthma. If you notice a lot of dust build up around your registers, suffer from allergies or frequent headaches, notice an increase in your utility bill, you may be due for a duct cleaning.

Residential ducts should be cleaned every 3 to 5 years.

We clean the following:

- Furnace

- Air Exchanger

- Dryer Vent

- Bathroom Fan

- Kitchen Hood Exhaust Fan

Dryer vents should be cleaned once a year to prevent lint build-up in the exhaust, which is a fire hazard! With our equipment we can clean your dryer vent from inside behind the dryer and outside. We clean both sides when accessible to guarantee a clear duct. (as demonstrated in our videos below)

What to expect:

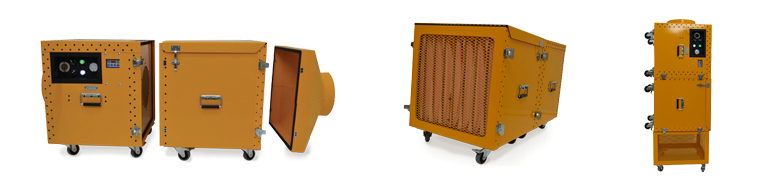

For an average home including a furnace and up to fifteen supply/return ducts it will take approximately four hours of time to clean your ventilation system. We will enter you home with a “dust collector” a.k.a. negative air pressure machine which will be brought close to your furnace. Our dust collector is capable of vacuuming 3000 cfm (cubic feet per minute). Access will be cut in your main supply and return ducts to hook up the dust collector to the duct. Before we can start the work, you will be asked to turn off your furnace. For your comfort a few portable heaters will be available to you for the duration of our visit.

All supply and return registers or diffusers will be removed and the ducts will be covered with adhesive plastic to create a maximum suction effect. An air compressor will be set up and the hose with compressed air will be taken to the supply duct located furthest from your furnace. We also bring an industrial vacuum cleaner with dual motor and Hepa filter to first vacuum the debris in and around the duct. We will than use a hose with compressed air and pneumatic whip to loosen up the dust and dirt buildup inside your duct and push it towards the main duct where the dust collector is hooked up. Once that is done, we degrease inside the duct and the register or diffuser. We than cover the duct with the register or diffuser and move on to the next duct to repeat the same procedure and so on. Once we are done with the supply air ducts we move the dust collector to the return air duct branch and repeat the same procedure as with the supply air ducts.

Upon finishing the cleaning of all supply and return ducts throughout the home, we move to the furnace room to clean the main ducts, using extendable brushes to agitate the debris inside the main supply duct, and once all the dirt is loosened up, we pull it inside the dust collector with a reversed air pneumatic whip. The same cleaning procedure is done with the return duct and the return plenum up to the filter. The filter will be removed, and vacuum cleaned or replaced if you have a replacement filter available. Upon request we can fog your ductwork with biocide which is an antibacterial product. This is optional and is included in the price of the duct cleaning.

At this point we remove the dust collector and cover the openings in your ducts with sheet metal plates and seal them off with foil tape. You will now be asked to turn on your furnace. Finally, we pack up our equipment and show you the pictures we took before and after the cleaning of your ducts to show what has been removed from your duct system.

Why choose a portable dust collector over a truck mounted dust collector?

There are several advantages to choosing a portable dust collector.

- Distance is not a factor, as it will be carried inside your home close to the furnace, wherever the location; in the basement, in the attic or on the fifth floor of an apartment building. The dust collector is designed to fit in small spaces and can either be assembled horizontally or vertically according to the space. Truck mounted dust collectors are very limited at how far they can reach.

- No energy loss, as the dust collector is inside your home, and the hose which is connected to the dust collector and your main duct are within a few feet proximity. Truck mounted dust collectors still need to have the hose attached to your main duct in your home, which means either your door or window will be left open for several hours and will affect the temperature inside your home. During the warmer months this may mean bugs will enter your home or your pet may wander off.

- Distance is a factor, the portable dust collector is hooked up within a few feet of your main duct, which means it loses absolutely no power vacuuming the dirt at 3000 CFM (cubic feet per minute). A truck mounted dust collector is parked far from your furnace, and therefore will have to struggle against more static pressure that can reduce the suction airflow rate. So even if they offer fantastic airflow rate, it will be reduced by the distance it has to go to reach your furnace.

[metaslider id=384]

AC Cleaning

With summer around the corner, soon comes the time to turn on the air conditioning to keep your home cool. You may notice that your electricity bill is going up more than expected or your house is not cooling enough .

This will be an opportunity for those who have an A/C or wall heat pump to call our HVAC technician to clean their system.

For latecomers, do not worry. You can have your system cleaned at any time of the year provided the weather conditions allow you to clean the coils of the outdoor unit which acts as a condenser in summer for the A/C and an evaporator in winter for a heat pump.

An AC system has two types of coils, condenser coils and evaporator coils usually made of copper tubes with aluminum fins.

The role of the evaporator (indoor coil) for A/C application in summer is to absorb the ambient heat of your home into the refrigerant circulating in the copper tube. This heat is rejected outside the house by the condenser (the outdoor coil). Therefore, the condenser blows hot air in the summer.

For a heat pump application, the opposite phenomenon occurs thanks to the reversing valve. Even in a climate where the outdoor ambient temperature drops below 0˚C, there is a possibility for your evaporator (outdoor coil) to absorb the heat from this cold air up to a threshold of minus 12 ˚ C into the copper tube. This heat is then released in the condenser (indoor coil) that blows hot air into your home.

To keep your system working optimal, it is important to clean the evaporator and condenser on a regular basis so that they do not behave like insulators that would prevent heat transfer.

- Systems operating with dirty coils consume a lot more energy which result in higher electric bills

- Dirty system's cooling capacity can be reduced by up to 30%. Dirty coils increase the operating pressure and temperatures that can break down the compressors' lubricant and can result in compressor failure. A failed compressor means no cooling and a costly repair.

- Fan blades also collect dust and dirt that cause the blade to become coated making it difficult to move air and reducing the amount of air moved.

- A Dirty system can reduce the air quality in your home.

- Dirt can clog the drain and cause your system to leak

We use SpeedClean® Coiljet® coil cleaner system, a specialized system that combines water pressure and alkaline biodegradable coil cleaner to remove scale deposits, dust, debris, grease, rust and organic growth.